Safety Switches for Material Handling Plants

Most rugged, reliable and dependable range of safety switches, conveyor safety switches, electronic switches, electronic conveyor switches etc. A must for every conveyor and material handling plant. Thousands of switches are in use at cement, fertilizer, steel, mining and power plants. Specially developed field mounting enclosures with added safety features.

Control Instruments Send Enquiry

Our Control Instruments are used in almost all the industries for indication, data-monitoring & control panels such as temperature, time, counting, RPM, humidity etc.

- Material Level Switch Tilt Switch

- Chute-Block Detector

- Boot Level Indicator

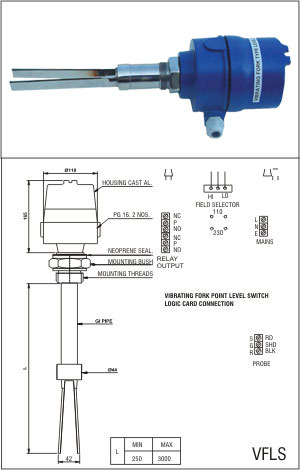

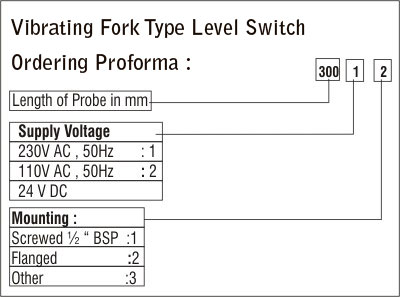

- Vibrating Fork Type Level Switch

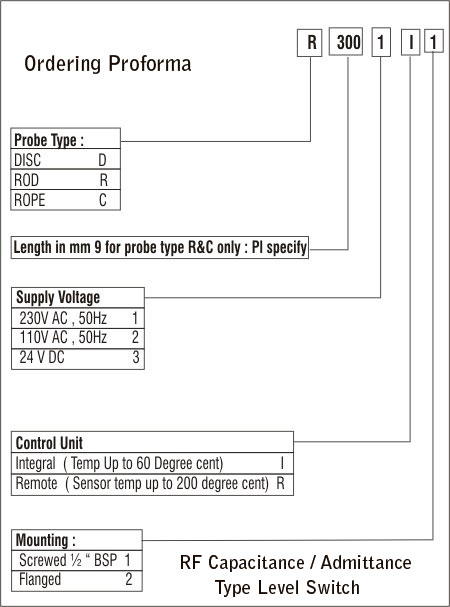

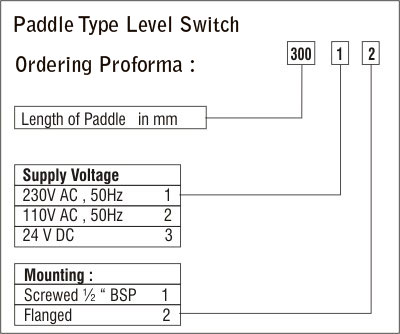

- Paddle Type Level Switch

- Ultrasonic Level Transmitter

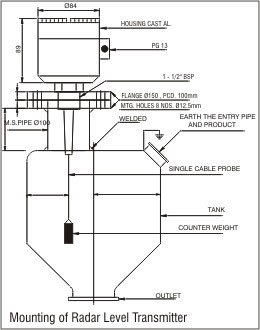

- Radar level Transmitter

- Anti collision switch for cranes

- De-Interlocking Switches